Xinguo’s Honyaki are special items in many ways, the look, the steel and even the maker and region of production. These blades are truly remarkable to look at, and I don’t want that statement to overshadow the performance of them. It is the first item we stock made by Xinguo’s team and I think as a complete package, this Blue Super Honyaki really stands up to this studio’s motto: Pursuit beyond high proficiency in forging and polishing, but seek strong expression in different products.

The elephant in the room is, these are Mizu Honyaki Blue Super blades. The Blue Super Honyaki are already pretty hard to find due to the difficulty and high failure rate, but Xinguo pushes this even further by performing a water quench rather than a safer and perfectly viable oil quench. This brings the steel to its highest achievable hardness of 64-65 HRC, and allows a very thin and fine edge to be put onto them. Combining with a quite well controlled convex grind, the cutting performance can go toe to toe with some of the Japanese counterparts that produce similar knives.

The appearance would be a totally different story, and I think Xinguo has achieved their goal of seeking strong expression with this knife. This surface of the knife is entirely covered by very strong alloy banding, and the fine glitter-like texture has such a strong texture that makes me think of the legendary Wooz steel. This alloy banding is a phenomenon commonly found on alloy carbon steel especially those with a lot of Tungsten, but this is not common especially like this one with strong contrast. To intensify this look, the blade is etched to increase the contrast. The harmon turns to a light grey colour with brighter banding over it, but the hardened steel shows a mesmerising blue sheen, which looks breathtaking when paired with the mirror polishing and the white banding floating over it.

When having a single light source shined onto the blade, it can present different look at different angles, in some angle, the blade would appears as a typical Honyaki with hazy hamon and dark polished hardened steel, i you keep turning it, the hamon will start to pick up a golden sheen and reveal its second layer, then at certain angle, the allow banding will suddenly show up, drizzle the entire blade with texture. This is a very complicated knife that you can spend hours looking at it, and it just feels more impressive when you realise all of these are achieved by specific techniques applied to a monosteel blade.

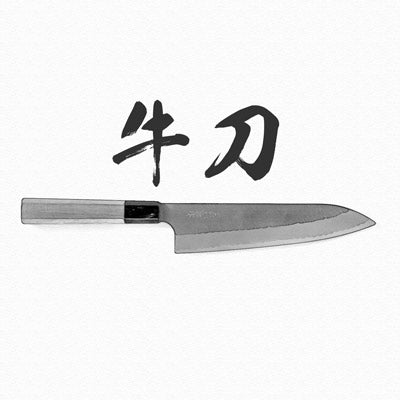

The knife takes a more Sakai style profile, but made a bit wider than typical, although Honyaki tend to be some of the more “collector items” this board blade with a pretty thin edge would still be happy to chop through whatever you feed to it. For head chefs and collectors, this line offers a reasonable option for you to experience Honyaki Ownership, but I say the price speaks very little about how well these blades are made, whether in terms of fit and finish, craftsmanship or overall design and aesthetics.