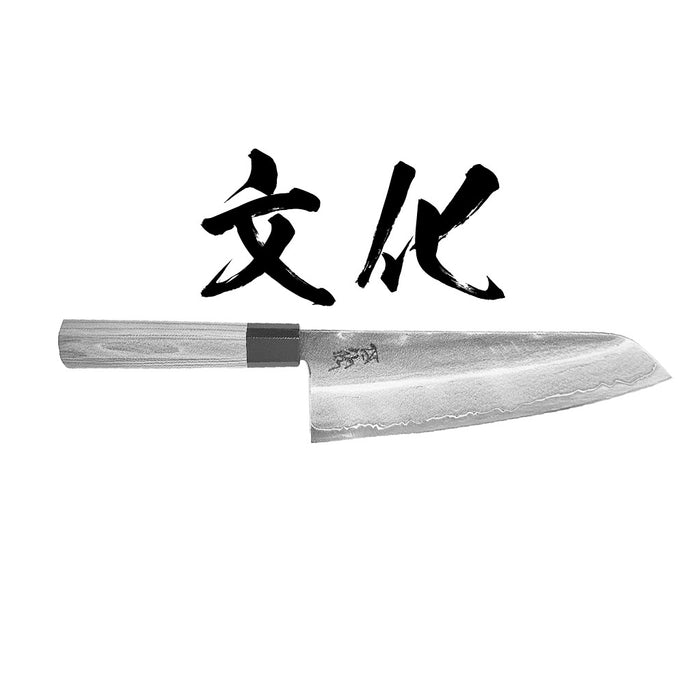

Hado/Ouru SLD line is a lineup with a bit complex background, made with an excellent material that has great edge retention, maintainability and aggressive edge, this forged lineup has a heavy duty blade that is sharpened pretty thin. It is a beauty and a beast, a beloved weapon for those who like to weld tip heavy knives, and its identity took me some digging to find out.

The SLD steel strictly speaking is not a stainless steel, although having a pretty high chromium level, the high carbon content results in a lot of chromium carbides, leading to less chromium participating in rust resistance. But, unlike other semi-stainless such as SKD, SLD will barely pick up a patina, so if dried properly, it can be very easy to take care of, and its edge when dulls, will retain some of the aggressive feeling like a carbon steel edge does.

To talk about the build, I think it’s important to figure out its creator. Although labelled with “Hado Ouru”, I believe this is not a knife produced in Sakai. Ouru or Oul are just the different spelling of the same brand “翁流”, And Oul Sakai is the older name of the knife brand under Fukui Craft Co. before they started their in-house atelier Hado in 2019. The knife is sharpened with a rather low Shinogi line, instead of the typical super wide bevel design Hado uses, its forging keeps the strong taper in the spine and a lot of thickness in the blade, and overall the style is full of Sanjo features. I found some Ouru knives with a similar SLD finish featuring a very familiar handle, identical with the Hocho Kobo series from Tadafusa, then it all started to make sense. Judging by the features of these knives, I can almost certain these are knives commissioned by Ouru to Tadafusa, these products are kept and carried over after the founding of Hado, and they are sold under the Hado/Ouru name with Ouru engraving to differentiate from the sharpened-in-house Hado knives.

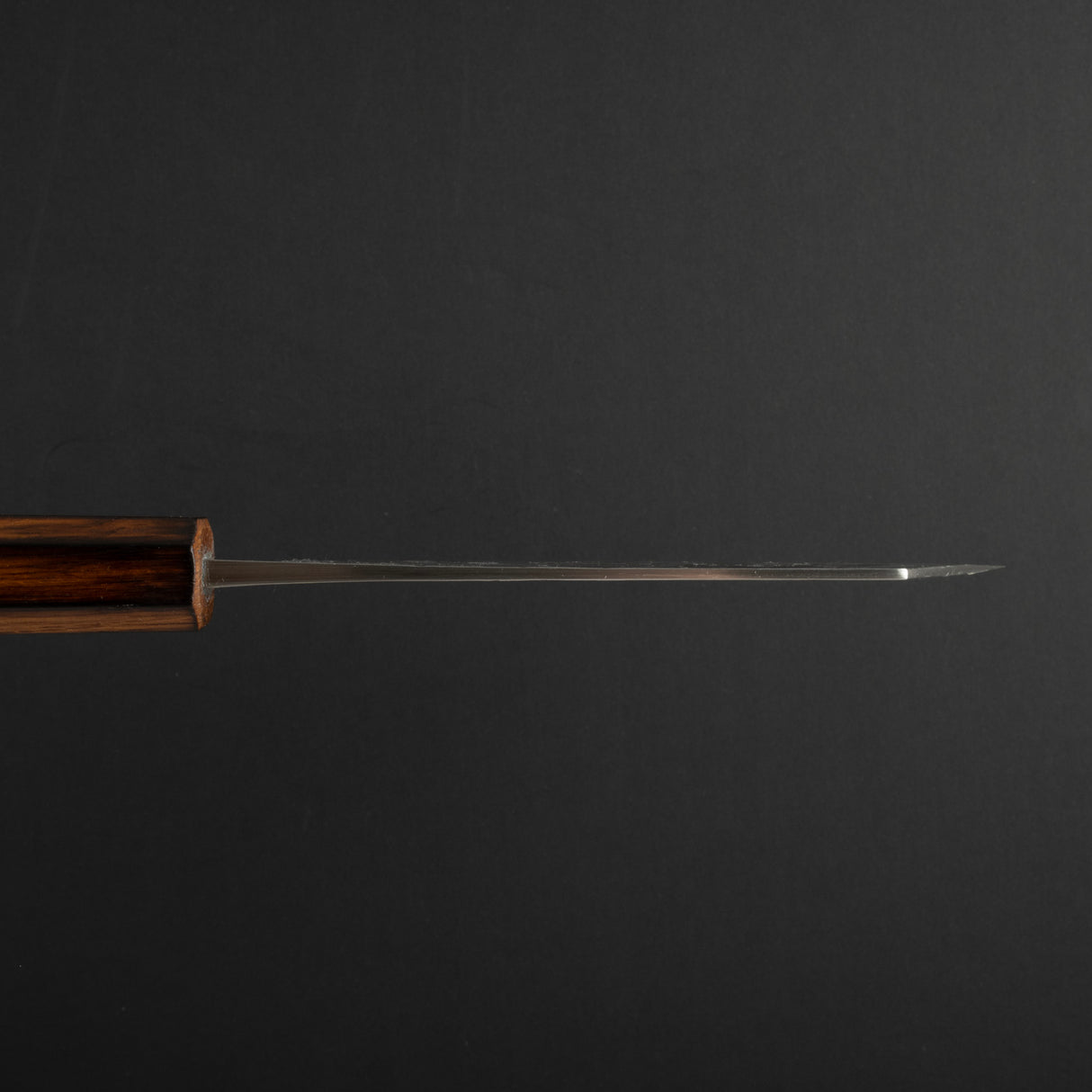

Tadafusa’s approach on sharpening is quite different from Hado, they kept the bevel rather thick and paired it with a convex grind, this is a design that emphasises food release, and indeed we found potato slices barely get caught on the blade. Although the thickness of the knife does cause some difficulties when dealing with dense and tough roots, the low thickness behind the edge still allows the knife to enter most of the food with little resistance, and the weight of the knife will carry the cut through the food with great smoothness.

This is a very Sanjo knife under a Sakai brand, and I quite recommend it for users who like that reassuring weight from a heavy knife. The hand forging, rustic Nashiji finish and smooth hand sharpening lead to a very characterful lineup. It is a great line to work with for professionals or knife enthusiasts with its great cutting characteristics.