Exotic: Genkai Masakuni (玄海正國) Mizu-Honyaki Yanagiba 300mm

Exotic: Genkai Masakuni (玄海正國) Mizu-Honyaki Yanagiba 300mm is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Detailed Specifications

| Line | Genkai Honayki |

| Profile | Yanagiba |

| Bevel Type | Single Bevel |

| Weight | 232 g 8.18 oz |

| Edge Length | 292 mm .11.5 inch |

| Heel Height | 34 mm .1.34 inch |

| Width @ Spine | 3.8 mm 0.15 inch |

| Width @ Mid | 3.2 mm 0.13 inch |

| Width @ 1cm from Tip | 1.3 mm 0.05 inch |

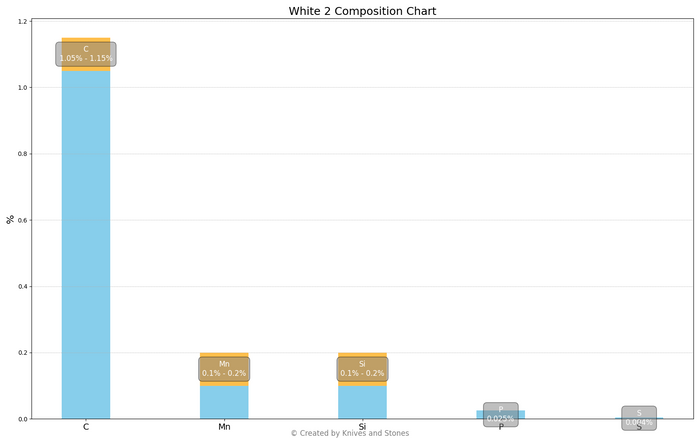

| Steel | White 2 / Shirogami #2 | Carbon |

| Blade Construction | Honyaki |

| Hardness (HRC) | 60 - 64 |

| Surface Finish | Mirror Polish |

| Handle | Special Handle |

| Region | Other |

| Best for |

|

Discover the exceptional craftsmanship of the Genkai Masakuni Mizu-Honyaki Yanagiba 300mm — a masterpiece that embodies the pinnacle of traditional Japanese blade-making.

This exquisite single-bevel knife is purpose-built for professional sashimi preparation. Forged from Shirogami #2 carbon steel using the demanding mizu-honyaki process, it achieves remarkable hardness (HRC 60–64) while maintaining exceptional edge retention and sharpness.

The 300mm blade features precise proportions: a 292mm cutting edge, 34mm heel height, and a refined taper from 3.4mm at the heel to 1.3mm at the tip. Weighing 232g, it offers superb balance for effortless, precise slicing.

The knife is fitted with an elegant stabilized maple handle accented by a mosaic pin, paired with a matching maple saya, combining refined aesthetics with everyday functionality. Each piece is test-cut in store to ensure peak performance.

An ideal choice for professional chefs and discerning collectors, the Genkai Masakuni Mizu-Honyaki Yanagiba represents the ultimate expression of Japanese knife artistry.

Care Instruction

- Don't cut hard things! Japanese knives are brittle so bone hacking is a NO NO!

- Wash with neutral detergent after use, and wipe dry;

- Please don't wash knife with dishwasher, it will damage the wood handle;

- Be careful not to leave the knife close to a heat source for a long time;

- It is a lot more dangerous to cut with a blunt knife than a sharp knife!

- It is best to sharpen a Japanese knife regularly on a waterstone.

- Oil the (carbon) knife if storing for an extended period of time to prevent rust.